Just returned from a fantastic conference in Denver Colorado, the 2014 SAE Thermal Management Systems Symposium, which this year had the highest attendance ever with increasing participation from European (Renault, Jaguar Land Rover, BMW etc) and Asian OEMs (Honda, Hyundai etc).

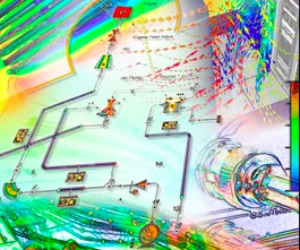

There were a lot of interesting presentations and concepts explored on recovering waste heat and efficient energy management in the vehicle.

Here are my 3 key take aways that I’d like to share

Active Thermal management – and then some more…

A few papers discussed active thermal management which was more about active energy management based on what the vehicle was doing at that very specific instant. An example of this is a GPS guided accessory management where, with a hill approaching, the Coolant Control Valve (or an Electronic Thermostat) would open fully dropping the coolant temp by a few degrees (2-3 deg) and enabling the fan to be off for a longer period of time during the hilly section. The other example is to use the compressor during braking to charge the AC system and cool the evaporator down to 2C and then turn off the AC until really needed. The blend door keeps the duct out temperature constant!

R1234yf refrigerant to replace R134a.

This is an EPA mandate coming up in 2021 for new light duty vehicles which bans 134a. R1234yf, with a significantly lower GWP potential was discussed as a very likely alternative with a few million cars with 1234yf already on the road today. The downside however is that 1234yf is more flammable. EPA encouraged further testing by individual OEMs on alternatives. GM presented a fantastic paper that used fault-tree analysis to analyze various scenarios of accidents and how 1234yf could come in contact with at least 700C to ignite. It showed the increased risk of fire from 1234yf was lower than dying in regularly scheduled air travel in a developed country.

Waste heat recovery – A dedicated session, with very similar approaches and a promising technology!

Most WHR papers focused on using Organic Rankine cycle (HFC-245fa made by Honeywell) to extract waste heat from the exhaust. A practical solution showed that ORC could generate a net of 2.2kW!. This is non-trivial, generating enough power to cover most, if not all of the accessory loads. They key to practicality will be in the weight and cost of the system, i.e., the cost/energy recovered ratio! I will watch this space closely.

Though the title of the conference was “thermal” management, lines were blurred, for the right reason, with “energy” management, with studies exploring overall energy available at the vehicle and the best use of available energy from the fuel. This is right approach in my opinion. We should all be using energy as a reference, as in, “energy to cool the cabin”, “energy to run the fan”, as opposed to heat loads and power.

Great conference and I will look forward to this in Troy, MI next October!